Everything About Oil Field Equipment and Pipeline Equipment: Trick Insights and Essential Details

Oil field equipment and pipeline systems play a pivotal role in the oil and gas market. They are essential for the reliable extraction and transport of hydrocarbons. Key elements, such as drilling rigs and tank, directly impact functional success. Advancements in modern technology promise to improve security and efficiency. Comprehending these components is vital for anybody entailed in or curious about this intricate industry, as it sets the stage for deeper expedition of sector practices.

Summary of Oil Field Equipment

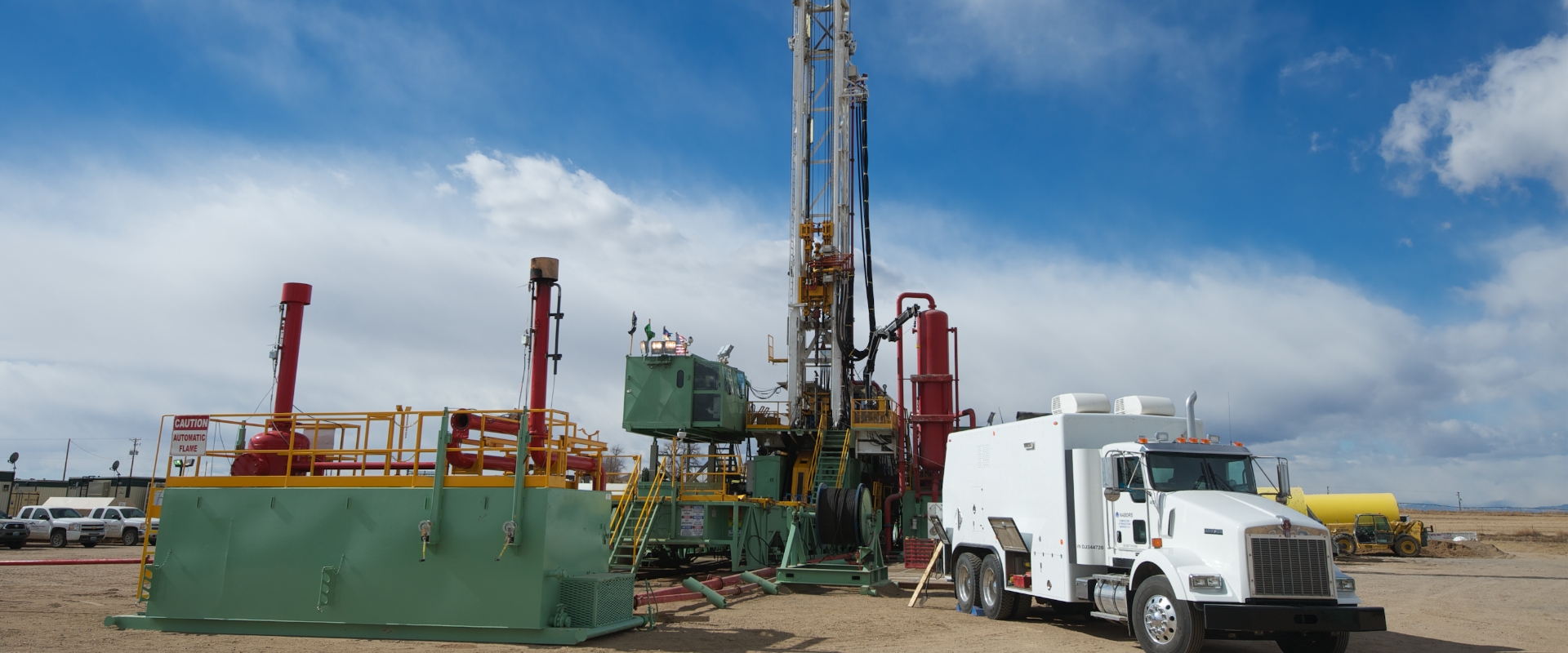

As the demand for oil remains to grow, understanding the tools made use of in oil fields comes to be significantly crucial. Oil field equipment includes a large range of equipment and tools vital for exploration, removal, and handling. Secret components consist of drilling rigs, which are important for getting to oil reservoirs, and manufacturing equipment, such as separators and pumps, that assist in the removal process. Superior Oilfield Rentals oilfield. Furthermore, storage space tanks play a considerable role in holding petroleum prior to transportation. Safety equipment, including blowout preventers and pressure gauges, ensures functional safety and security and efficiency. Each item of devices functions cohesively to optimize manufacturing and maintain reliable workflow. Experience with this equipment is necessary for specialists in the sector to assure successful procedures and adherence to safety standards

Types of Drilling Rigs and Their Applications

Drilling rigs function as the foundation of oil removal operations, with numerous kinds designed for particular geological problems and operational needs. One of the most common types include rotating drilling rigs, which make use of a revolving drill bit to penetrate the earth, and cord device rigs, known for their percussion boring technique. For overseas procedures, jack-up rigs and semi-submersible rigs supply security and support in marine atmospheres. Furthermore, directional exploration rigs enable drivers to pierce at angles, getting to down payments that are not up and down available. Each rig type has unique advantages, enhancing effectiveness and safety based on the drilling atmosphere. Choosing the ideal gear is essential for making best use of resource removal while lessening environmental impact and operational prices.

Essential Pipeline Equipment and Their Functions

Pipeline facilities is important for the transportation of oil and gas from removal sites to processing centers and end-users. Various crucial tools elements facilitate this process. Pipes themselves Check This Out act as the primary avenues, made to withstand high stress and corrosive materials. Pump stations are essential for keeping flow by boosting stress along the pipeline. Shutoffs play a vital function in regulating flow and separating areas for maintenance. In addition, installations and connectors assure protected joints in between pipe areas. Keeping track of systems, consisting of flow meters and stress sensors, are essential for discovering leaks and maximizing circulation rates. Lastly, pigging tools is employed for maintenance and cleaning, securing pipeline integrity and performance. Together, these components develop the foundation of a reliable pipeline system.

Advancements and Technologies in Oil and Gas Equipment

Safety And Security and Upkeep Practices in the Oil Market

While the oil industry has actually made considerable strides in technology and efficiency, the sites value of durable safety and upkeep methods can not be overemphasized. Reliable safety procedures are important to protect employees and the setting, reducing the danger of crashes and spills. Routine assessments and upkeep of tools assistance identify potential problems prior to they rise, guaranteeing functional stability. Educating programs for workers are important, stressing the value of safety and security recognition and emergency situation response procedures. Additionally, adherence to industry regulations and requirements promotes a culture of safety. Implementing innovative monitoring modern technologies can better boost upkeep methods, allowing for real-time assessments of tools problems. Eventually, prioritizing security and maintenance is integral to the sustainability and success of the oil market.

Frequently Asked Concerns

What Are the Ecological Effects of Oil Field Equipment?

The environmental impacts of oil field equipment include habitat damage, water contamination, and air contamination (Superior Rentals near me). Furthermore, tools malfunction can lead to spills, detrimentally impacting wild animals and environments, highlighting the demand for rigorous policies and surveillance

How Is Oil Field Equipment Transferred to Remote Locations?

Transporting oil field equipment to remote areas often involves specific cars, helicopters, or barges. Logistics firms coordinate paths, making certain devices gets here securely and efficiently, taking into consideration surface and availability to reduce delays and make the most of efficiency.

What Governing Criteria Govern Oil Field Equipment?

Regulative requirements regulating oil field equipment primarily consist of safety, environmental management, and operational efficiency standards. Agencies such as OSHA and EPA enforce these guidelines to guarantee secure practices and reduce environmental effect in oil removal procedures.

What Skills Are Required to Run Oil Field Machinery?

How Do Oil Costs Affect Equipment Need and Usage?

Oil rates significantly influence devices demand and usage. Greater prices normally result in raised exploration and manufacturing activities, driving need for machinery. On the other hand, lower costs might result in reduced operations and reduced need for tools.